- Food processing equipment

Applications

Products

- Washing & drying systems

- Service

Menu

Home > Food Processing > Products > Vacuum packers > Double chamber > Stand Alone > VA 840

Chamber dimension: 730 x 1100 x 280 mm

Machine dimension: 1213 x 2420 x 1597 mm (L x W x H)

Seal bar: 2 x 1100 mm

Pump capacity: 300 m³/h

Machine cycle: 15-40 seconds

Digital control: 10 programs

Options: Accessories:

1-2 Cut-off/Bi active seal Zebra ZD410 thermal label printer

Liquid control Inclined insert plate

Sensor control Service kit for standard maintenance

Advanced Control System (ACS)

Automatic lid

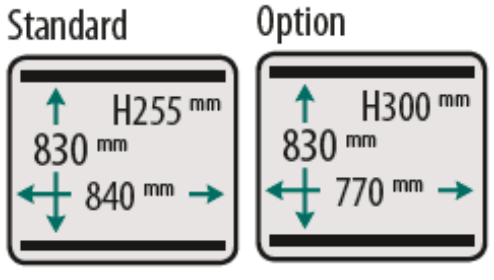

High lid 300 mm, with seal bars 2 x 770 mm

Gas flush (incl. pressed air connection)

Preparation for external pump

Heating element for vacuum valve

| Seal Systems | The right seal solution protects products efficiently against external elements. Cretel offers several seal systems for your specific application. This depends on the type of vacuum bag (PA/PE, shrink bag, bags with aluminum coating), thickness of the bag, the desired seal and other requirements. Request the seal options available for the desired model. |

| Gas Flush | Prior to the seal phase, a gas or nitrogen can be added. Cretel vacuum packaging machines can be equipped with the option Gas flush or Modified Atmosphere Packaging (MAP). It depends on the product which gas is most suitable. Your supplier can inform you best which is the optimum composition for your application. Please contact us with your specific gas requests. |

| Sensor Control | Vacuum packaging machines equipped with Sensor control calculate when the pre-set percentage has been achieved. In other words, the desired end vacuum is always reached, regardless the volume. That is the main advantage of Cretel's option Sensor Control. Very practical to vacuum pack various amounts and types of products. |

| Liquid Control | Wet and liquid products quickly reach their boiling point during the vacuum packaging cycle. Reducing the pressure in the chamber below atmospheric pressure causes fluids to boil at room temperature and cooks products when cold. The Liquid control sensor detects the evaporation of the liquid product. The machine then stops extracting the air and proceeds automatically with the next phase, the sealing of the vacuum bag. |

| Advanced Control Systems | The Advanced Control System includes unique features, special options and intelligent functions that add significant value to your vacuum packaging operations. LCD panel, Software in 5 languages, 20 program memory, USB connection to upload programs, Standard Sensor control, Label printer compatibility, HACCP compliance, Secured multi-level access, Online programming |